Every minute a commercial vehicle spends off the road is a direct hit to your bottom line. In the fast-paced world of urban logistics, where every delivery or job counts, maximizing uptime is crucial. This article explores some causes of downtime and offers strategies to minimize its impact.

Mục lục

The Rise of Urban Logistics & Last Mile Delivery

Online shopping has surged in recent years, driven by factors such as convenience, product selection and competitive pricing. During 2022, e-commerce sales in the U.S. increased by 7% due to the shift towards online shopping. Projections are that e-commerce will make up 41% of all retail sales worldwide within the next 4 years, with the last mile delivery market having a valuation of $288.9 billion by 2031.

Approximately 80% of the U.S. population resides in urban areas. Urbanization is increasing, with 85% of people expected to live in cities by 2030. The World Economic Forum predicts that by 2030 there will be a 78% increase in last mile deliveries in urban areas.

More people are shopping online and living in cities, leading to more packages to deliver in busy areas. This has made the process of delivering packages to their final destination more difficult and complicated for logistics companies. Keeping your fleet moving is more important than ever, ensuring your revenue.

The Challenges of Last Mile Delivery

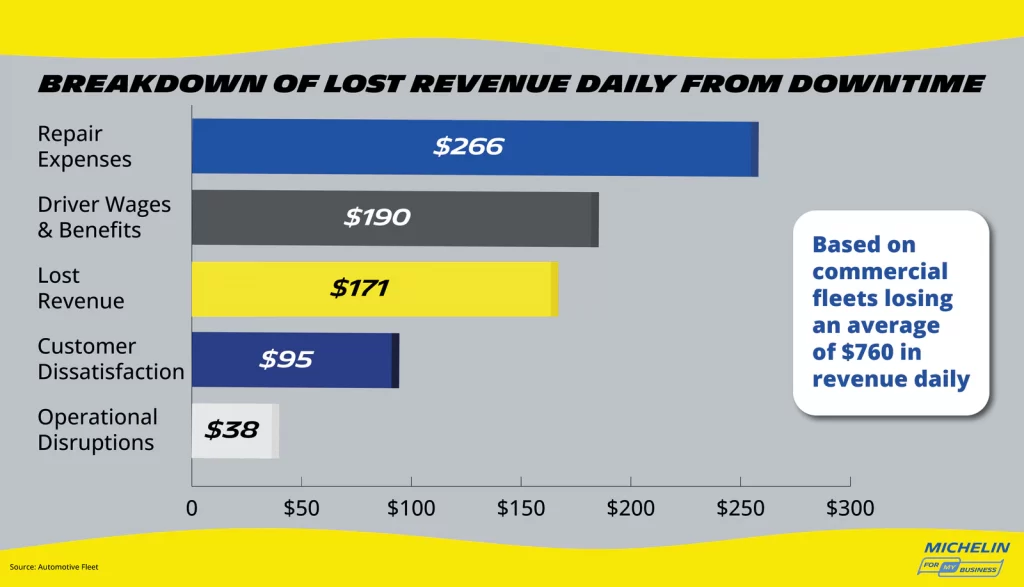

Downtime is expensive. For every hour of unplanned downtime, commercial fleets lose an average of $760 in revenue daily. This can make fleet operating costs increase by up to 20% due to vehicle repairs, wages, delivery fees, rerouting costs, and fuel use.

Urban fleets face unique challenges that amplify the cost of downtime:

- Tight Delivery Windows: Urban consumers have grown accustomed to rapid delivery services, often with specific time windows. In the era of two-day shipping, downtime disrupts these expectations, leading to missed deliveries, customer dissatisfaction, and potential loss of business. This can significantly impact a fleet’s reputation and customer loyalty.

- Traffic Congestion: Urban areas are notorious for traffic congestion, and any delay caused by vehicle downtime exacerbates this issue. This can lead to increased fuel consumption, driver frustration, and additional operational costs. Furthermore, it contributes to the overall congestion problem.

- High Vehicle Usage: Urban fleets often operate at maximum capacity to meet the demands of the bustling city environment. When a vehicle is out of service, it creates a ripple effect throughout the operation. This can lead to route disruptions, increased workload for remaining drivers, and potentially missed delivery opportunities.

- Competitive Landscape: The urban delivery market is fiercely competitive, with numerous players vying for a share of the market. Downtime can provide competitors with a significant advantage, allowing them to capitalize on missed opportunities and gain market share.

The Cost of Urban Fleet Downtime

The downtime costs for urban fleets can vary widely, based on fleet size, vehicle type and location. The costs can add up quickly when your vehicle is off the streets. These can include:

- Repair Expenses: Unexpected breakdowns can lead to costly repairs, part replacements, and labor expenses. These expenses can eat into your profits.

- Driver Wages and Benefits: While the vehicle is sitting idle, do is the driver, resulting in accrued labor costs.

- Lost Revenue: Delays or breakdowns of the truck can result in missed or delayed deliveries, leading to money lost.

- Customer Dissatisfaction: When customers aren’t getting their deliveries, they get upset and complain. This can damage your business reputation and lose customers.

- Operational Disruptions: When a vehicle is not working, it can cause problems for your entire operation. This can result in delays, inefficiencies, and added stress for your team.

Do Tires Impact Downtime?

Many factors can contribute to downtime, from breakdowns and inadequate maintenance to traffic congestion and lack of parking spaces. In fleet management, you cannot control everything that causes downtime. Proper fleet management can minimize one common factor in fleet downtime: the tires.

Tire-related issues are a significant contributor to fleet downtime. Tire failures account for approximately 22% of commercial vehicle breakdowns.

You can take some simple preventive measures with your tires. Drivers should check their vehicle’s tires before the day’s deliveries to ensure the tires are properly inflated, aligned, and rotated.

Strategies to Maximize Uptime

To combat downtime, focus on these key areas:

- Preventive Maintenance: Regular vehicle inspections and maintenance can identify and address potential issues before they become major problems.

- Driver Training: Well-trained drivers can help prevent accidents and reduce wear and tear on vehicles.

- Route Optimization: Efficient route planning can reduce driving time, decrease fuel consumption, and lower the risk of breakdowns.

- Real-time Vehicle Tracking: Using technology to monitor vehicle location and performance can help identify potential issues early.

- Tire Management: Prioritize tire health through regular inspections, proper inflation, and alignment.

- Partner with a Reliable Tire Provider: Choose a tire partner that offers comprehensive support, including maintenance services and emergency roadside assistance.

Conclusion

Urban fleets face a relentless adversary in downtime, but a proactive approach can effectively manage it. By investing in preventive maintenance, driver training, and tire care, you can significantly improve fleet uptime and cost-savings

business.michelinman